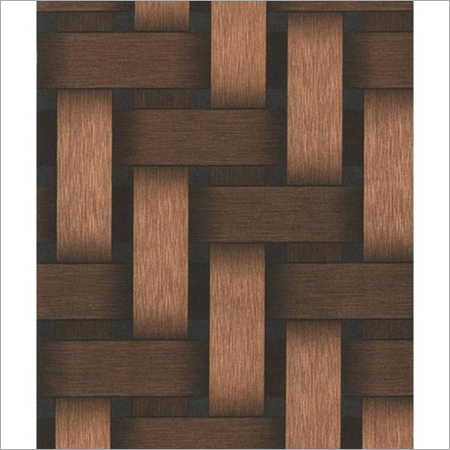

Decorative Bakelite Sheet

Decorative Bakelite Sheet Specification

- Resistance

- High resistance to heat, chemicals, and electricity

- Glue

- Other

- Thickness

- 0.5 mm to 50 mm Micrometers (um)

- Edge

- Smooth or beveled

- Product Type

- Decorative Bakelite Sheet

- Material

- Phenolic resin-impregnated kraft paper or fabric

- Surface Finishing

- Other

- Application

- Other

- Color

- Other

- Size

- 1220 mm x 2440 mm or as required

- Density

- 1.45 Gram per cubic centimeter(g/cm3)

- Tolerance

- 0.1 mm Micrometers (um)

- Moisture Content

- 6%

- Feature

- Fire retardant, durable, scratch-resistant, easy to fabricate

- Dielectric Strength

- 9 kV/mm

- Packing Type

- Standard export packing / bundles

- Flexural Strength

- 100 MPa

- Hardness

- Rockwell M95 - M100

- Temperature Resistance

- Up to 140C

- Water Absorption

- 1.5%

- Thermal Conductivity

- Low (approx. 0.25 W/mK)

- Grade

- Industrial and Decorative Grade

Decorative Bakelite Sheet Trade Information

- Supply Ability

- 1 Per Day

- Delivery Time

- 7 Days

- Main Export Market(s)

- Asia, Australia, Central America, North America, South America, Eastern Europe, Western Europe, Middle East, Africa

About Decorative Bakelite Sheet

We are supplying here the Decorative Bakelite Sheet that is a hard, dense material made by applying heat and pressure to layers of paper or glass cloth impregnated with synthetic resin. These layers of laminations are usually of cellulose paper, cotton fabrics, synthetic yarn fabrics, glass fabrics or unwoven fabrics. The Bakelite is made from carbolic acid (phenol) and formaldehyde and is referred to as a phenolic resin. Bakelite was the first thermosetting plastic. The offered sheet can be easily installed in various places for making them attractive. The Decorative Bakelite Sheet is very useful and easy to place.

Superior Electrical and Thermal Properties

Bakelite Sheets deliver remarkable electrical insulation, with dielectric strength 9 kV/mm and low thermal conductivity. Suitable for industrial environments, they ensure reliable protection and performance in electrical applications, making them a leading choice for insulation panels and components.

Durable in Harsh Environments

Built with phenolic resin and a fire-retardant formula, these sheets remain resistant to heat, chemicals, scratching, and moisture ( 6%). Their sturdy construction and high flexural strength make them ideal for paneling, countertops, and partitions in demanding or high-traffic areas.

Versatile Decorative Finishes

Available in glossy, matt, or textured surfaces with smooth or beveled edges, Bakelite Sheets fit various aesthetic and functional needs. Offered in standard and custom sizes and colors, they easily integrate into interior design for furniture, decorative wall panels, and more.

FAQs of Decorative Bakelite Sheet:

Q: How are Decorative Bakelite Sheets fabricated for custom applications?

A: These sheets are easy to cut, drill, and shape using standard woodworking or fabrication tools. Their smooth or beveled edges and thickness range from 0.5 mm to 50 mm allow precise customization for any size or design requirement.Q: What makes Decorative Bakelite Sheets suitable for electrical insulation?

A: Their dielectric strength of 9 kV/mm, low thermal conductivity, and high resistance to electricity provide reliable insulation and safety in electrical panels and components, making them ideal for industrial and commercial electrical applications.Q: When should I choose Bakelite Sheets for paneling or countertops?

A: Choose Bakelite Sheets when high durability, fire retardancy, chemical resistance, and easy maintenance are required. Their sturdy structure and attractive finish make them well-suited for both functional and decorative interior surfaces.Q: Where can Decorative Bakelite Sheets be used effectively?

A: They are widely used in furniture, countertops, partitions, paneling, interior decoration, and electrical insulation. Their durability and variety of finishes make them ideal for offices, homes, industrial areas, and public spaces.Q: What is the manufacturing process of Bakelite Sheets?

A: Bakelite Sheets are manufactured by impregnating kraft paper or fabric with phenolic resin, layering them, and curing under heat and pressure. This yields a fire-retardant, stable laminate with excellent mechanical and electrical properties.Q: What benefits do Decorative Bakelite Sheets offer over other laminates?

A: Bakelite Sheets offer superior resistance to heat, chemicals, and electricity, along with fire retardancy and scratch resistance. Their versatility in color, thickness, and finish makes them more adaptable than many conventional laminates.Q: How are Decorative Bakelite Sheets packaged for export?

A: They are packed in standard export packing or bundled securely to prevent damage during transit, ensuring they arrive in pristine condition whether supplied within India or shipped internationally.

Tell us about your requirement

Price:

Quantity

Select Unit

- 50

- 100

- 200

- 250

- 500

- 1000+

Additional detail

Mobile number

Email

We accepts only foreign inquiries.

|

PHENIX DECOR PRIVATE LIMITED

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

English

English Spanish

Spanish French

French German

German Italian

Italian Chinese (Simplified)

Chinese (Simplified) Japanese

Japanese Korean

Korean Arabic

Arabic Portuguese

Portuguese

Send Inquiry

Send Inquiry